Project Detail

Project: Western Union Unit 02

Equipments: Strainers

Date: May 2014 to September 2014

Vendor Location: Fabricator of Pressure Vessels in Tamaulipas, Mexico.

Witness on Hydrostatic Test per ITP-WU-194-QS-01-Item 06 and Hydrostatic Test Procedure QWU-193.8 Rev B.

Item Inspected: Strainer Tag-195-WU-01, Serial Number T44098.

Findings: Pressure Drop and Leak detected on Weld of Outlet Nozzle to Pipe Body. The following Steps were conducted by Vendor and Witnessed by Fraza Team to get properly Repaired the Weld Defect producing the Referenced Leak: Exploration by Grinding to Remove completely the lack of fusion detected. PT Examination on Explored Weld to confirm on sound metal. Weld Application by GTAW Process on Explored Weld from Inside and Outside.

Re-Inspection: PT Examination on Completed Weld Repair to confirm on Weld and adjacent base metal free of Defects. Hydrostatic Test conducted again in accordance with Documents Referenced Above, With No leaks and No Pressure Drops detected. See Photos on Leaks originally Detected.

Witness on Hydrostatic Test per ITP-WU-195-QS-01-Item 06 and Hydrostatic Test Procedure QWU-193.8 Rev B.

Item Inspected: Strainer Tag-195-WU-01, Serial Number T44099.

Findings-Test Results: Four Focused Locations showing Leaks detected on Base Metal of Casting Lower Manifold. Vendor QC Team has issued an Internal NCR, whose disposition from Vendor Engineering Team was Repairing by Welding the base metal area of Casting showing Leaks. Fraza Team has requested to Vendor QC Manager to wait for Disposition from Customer before any action be taken on Referenced Casting Lower Manifold.

Re-Inspection: Per Customer Disposition Lower Manifold Casting and all components welded to it have been replaced by Vendor. After Replacing of referenced ítems, Hydrostatic Test has been conducted again in accordance with Documents Referenced Above, with No leaks and No Pressure Drops Detected. See Photos on Leaks originally Detected.

Visual Inspection on Welds per ITP-WU-193-QS-01-Item 03, GA Drawing WU-5312-01 Rev 2 and Detail Drawing WU-320-03 Rev A.

Item Inspected: Strainer-Tag-193-WU-01, Serial Number T44097.

Findings: Joints Elbow item 5 to Pipe item 6, Casting Lower Head item 3 to Pipe item 2, Casting Upper Head item 2 to Elbow item 1 and Elbow item 1 to Pipe Item 3 specified to be Complete Joint Penetration per Welding Symbols from Vendor Drawings referenced Above, however all of them Observed with Incomplete Joint Penetration.

Re-Inspection: All needed repairs completed by Vendor in compliance to drawing requirements. See Photos on Described Issue.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Welding Defects and Leaks Hydrostatically detected, If Not Corrected/Repaired in timely manner at Vendor Shop.

Project Detail

Project: Royal Mines Unit 03

Equipments: 12” Strainer

Date: February 2009 to to March 2009

Vendor Location: Fabricator of Strainers in Tamaulipas, Mexico.

Visual Inspection per Inspection and Test Plan ITP-TO-12874037 Rev B Item 4, Customer Technical Spec 37245-0598 Rev C and Drawing- S-37245-0599 Rev 2.

Item Inspected: Vessel Shells Tag S5054-B and S5053-B.

Findings: Referenced Vessels fabricated from Welded Pipes SA-53 Gr-B ERW(Welded), however Main Nozzles of 12” Diameter observed oriented and located passing through the longitudinal weld seam of the shell pipes, Not acceptable to Note 3 of Fabrication Drawing S-37245-0599 Rev 2. Vendor has issued a Deviation Request to Final Customer trying to get approval on this Deviation, however it has been declined by Customer.

Re-Inspection: Per Disposition from Customer, both Vessels S5054-B and S5053-B have been Re-fabricated using new pipe shells. Both new Vessels Shells have been visually inspected and both of them comply to Note 3 of Referenced Drawing since now no nozzles pass through any longitudinal and circumferential weld seams. Addressed by Vendor. See Photo as illustration on referenced issue.

Review on Welder Qualification Records(WPQ’s) per Inspection and Test Plan ITP-TO-12874037 Rev B Item 2, Customer Technical Spec 37245-0598 Rev C and Drawing- S-37245-0599 Rev 2.

Item Inspected: Vessel Shells Tag S5054-B and S5053-B.

Findings: All Welders participating on this project have been qualified in GMAW Short Circuiting as Mode of Transference by Radiographic Testing, Not acceptable to paragraph QW 304.2 of ASME Code Section IX which for Mode of Transference Short Circuiting specifies for Mechanical Test(Bend Test) for Welders Qualification.

Re-inspection: Per Observation from Fraza Team, all welders have been Re-qualified by Mechanical Test(Bend Test) in accordance with referenced ASME Code Requirements. Addressed by Vendor.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Welders not qualified to ASME Code Section IX and Not Compliance to Project Requirements, If Not Corrected/Repaired in timely manner at Vendor Shop.

Project Detail

Project: South Energy Unit 01

Equipments: Engineered Strainers

Date: December 2009 to January 2010

Vendor Location: Pressure Vessels Fabricator in Tamaulipas, Mexico.

Visual Inspection on Surface Preparation and Painting per Inspection Attribute List # 12 and Specifications 465732-T-U-038 Rev 1 and 460715-T-U-036 Rev 0.

Item Inspected: Strainers Tag Numbers 12-HT-G-SYU-0056-A/B/C, 11-TH-SK-0139-A/B/C and 14-TW-IUN-087-A/B.

Findings: Referenced Strainers were not painted in interior surface, Not acceptable to Specification 465732-T-U-038 Rev 1 Section 8.9.2 which specifies for ¨Internal Strainer Body and Head shall have a proven marine or epoxy lining to be applied in the Sellers Shop. Also, Spec 460715-T-U-036 Rev 0 Page 7 Section 2.7.3-b)-2) specifies too for Painting to be applied in Exterior and Interior Surfaces.

Re-Inspection: Issue finally addressed/corrected by Fabricator in accordance with referenced Project Requirements. See Photo as Illustration on Referenced Issue.

Review on Inspection/Test Requirements per Inspection Attribute List # 14 and Specifications 465732-T-U-038 Rev 1 and 460715-T-U-036 Rev 0.

Item Inspected: Strainers Tag Numbers 13-WY-TRN-0760-A/B/C.

Findings: Referenced Strainers were painted in interior with a Epoxy Coating in accordance with internal Fabricator Standards, however this Applied Epoxy Coating in interior surface was not examined by a Continuity Test by a nondestructive detector as specified on Specification 465732-T-U-038 Rev 1 Section 7.13.2.

Re-Inspection: Vendor has conducted a Continuity Test by a nondestructive detector with aceptable results as specified per Project Requirements. See Photo on Continuity Test as conducted.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Reworks at field site per unacceptable issues on surface preparation, painting and omitted tests on painting, If Not Corrected/Repaired in timely manner at Vendor Shop

Project Detail

Project: South Coast Unit 01

Equipment: Process Strainers

Date: August 2011 to September 2011

Vendor Location: Fabricator of Strainers in Tamaulipas, Mexico.

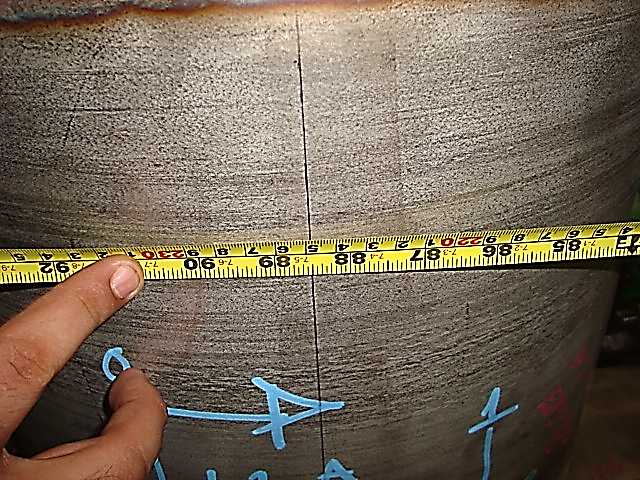

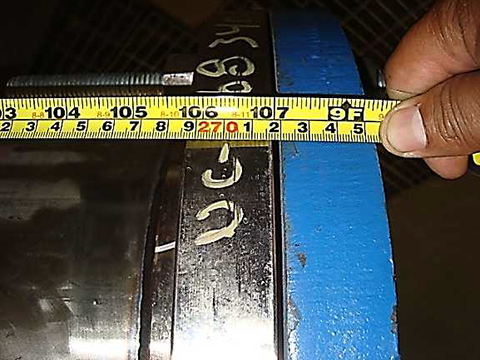

Dimensional Inspection per Inspection and Test Plan AYT-231-01 Rev 1 Item 3 and Drawings R-4301-06 Rev C.

Item Inspected: Process Strainer Tag 76258-Serial Number G29190AB.

Findings: Overall Wide Flange face to Flange Face: Specified Dimension, 107 ½”, Tolerance per referenced Drawing: plus/minus ¼”.- Actual Dimension 107¨-Out of Tolerance.

Re-Inspection: Per Customer Disposition, Correction conducted by Vendor to bring the referenced dimension within tolerances. See Photo as illustration on referenced issue.

Visual Inspection per Inspection and Test Plan AYT-231-01 Rev 1 Item 4 and Drawings- R-4308-04 Rev D.

Item Inspected: Process Strainer Tag 76260-Serial Number G29188AB.

Findings: Support Legs Item 32/33 No continuously welded all around to Tee Item 22 as specified on referenced Drawing. No Acceptable to Customer Technical Specification 851765-R-TY-054232 Section 4.5.1 Rev 3.

Re-Inspection: Vendor has completed the weld all around of Support Legs to Tee"s as per Drawing Requirements. See Photo on Referenced Issue.

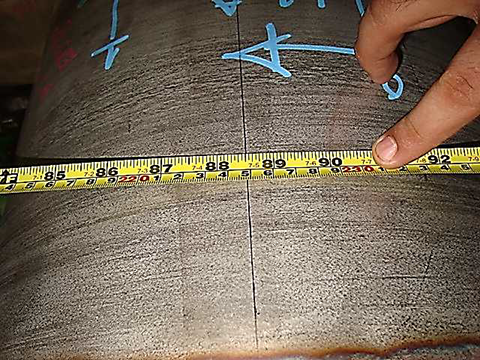

Dimensional Inspection per Inspection and Test Plan AYT-231-01 Rev 1 Item 3 and Drawings- R-7806-02 Rev 2.

Item Inspected: Process Strainer Tag 16242-Serial Number H39291291A.

Findings: Overall Wide Dimension, Pipe Centerline to Pipe Centerline: Specified Dimension 89”, Tolerance per referenced Drawing: plus/minus1/4¨- Actual Dimension 88 1/2¨-Out of Tolerance.

Re-Inspection: Per Customer Disposition, Correction conducted by Vendor to bring the referenced dimension within tolerances. See Photo as illustration on referenced issue.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Reworks at field site per unacceptable issues on welding and dimensions If Not Repaired in timely manner at Vendor Shop.

Project Detail

Project: North Western Mountain Unit 03

Equipments: Strainers

Date: May 2014 to July 2014

Vendor Location: Fabricator of Strainer Equipments in Tamaulipas, Mexico.

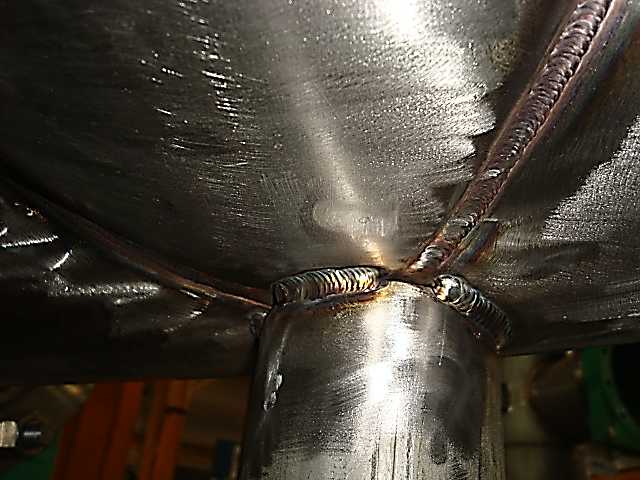

Visual Inspection on Welds per Vendor Inspection Plan ITP-TCK-5030- Rev 1 Item 03 and Vendor Drawing T6312-04 Rev 3.

Item Inspected: Strainer Tag-6509-WY-0035, Serial Number R54498.

Findings: Joints between Inlet/Outlet Nozzle necks to Shell Pipe, specified to be Complete Joint Penetration per Welding Symbols from Vendor Drawing referenced Above, however, Observed with Incomplete Joint Penetration on internal Side of the Joint.

Re-Inspection: Repairs completed by Vendor to achieve CJP on referenced Joints as specified. See Photo as Illustration on referenced Issue.

Benefits to Our Customers: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Welding, If Not Corrected/Repaired in timely manner at Vendor Shop.

© 2019 Fraza Inspection Company - All Rights Reserved