Project Detail

Project: Black Mountain Unit 01

Equipment: Exhaust Baffles/Ladder & Platforms

Date: May 2017 - June 2017

Vendor Location: Fabricator of Exhaust Baffles/Ladder & Platforms in Coahuila, Mexico.

Dimensional Inspection per Manufacturing Quality Control Plan 20437-BM-001 Rev A Item 8 and Drawing 20437-058200 Rev B.

Item Inspected: Baffles Series 200.

Findings: Dimension inside the support retainers of baffle 321 7/8” +/- 1/8”, Critical Dimension affecting the field assembly to Silencer Shell, Actual dimension as Measured, 321 9/16”(Minus 5/16”), Out of Tolerance per referenced Drawing and per Customer Tolerances Standard BM-STD-021 Rev 1, Section 5.3.

Re-Inspection: NCR-20437-NR-96 has been open on this Deviation and the disposition from Customer has been to correct the referenced dimensión on all Baffles in accordance with Project Tolerances. Vendor has worked to correct the referenced Critical Dimension on all Completed Baffles, as well accordingly Fraza Team has re-inspected on them with aceptable Results. See Photos on referenced Dimensional Deviation.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on deviations of Critical Dimensions affecting the Field Assembly, if Not Corrected/Repaired in timely manner at Vendor Shop

Project Detail

Project: Black River Unit 03

Equipments: Exhaust Baffles

Date: October 2017 - November 2017

Vendor Location: Location: Fabricator of Exhaust Baffles in Coahuila, Mexico.

Witness on GTAW Application per ITP-204-BR-MQC-03 Rev 1, Item 15 and Drawing 204-048300 Rev 2.

Item Inspected: Baffles series 048300, inspected on Welds of Channel Formed Item 5 to Formed Angle Item 9.

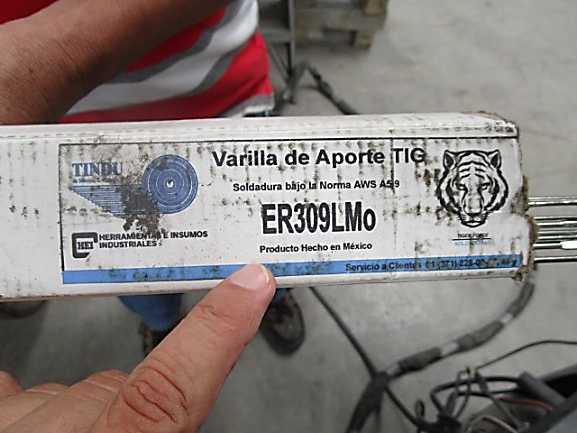

Findings: Filler Metal being used, rods identified just as ER309, not in accordance with approved welding procedure WPS-015/16 Rev 2 which specifies for a Filler Metal ER309LMo. However, the container where the mentioned rods were, traceable to Lot Number V7600 is identified as per specified AWS Classification ER309LMo. After detection by Fraza Team of this discrepancy, Vendor has conducted a Spectrophotometry Test on used filler metal ER309 through an external Laboratory, Test Results, Chemical Element Chrome, Specified Range, 23-25%, Actual per Test Report, 20.96%, as well Chemical Element Copper, Specified Range, 0.75% Maximum, Actual per Test Report, 0.96%, both Chemical Elements, Out of Specified Range per Specification ASME SFA 5.9-ER309LMo.

Re-Inspection: NCR-20436-01 was generated and per Customer Disposition all baffles shall be Reworked on welds in accordance with New Qualified and Approved Welding Procedure Number 025/17 for Base Metal SA 240 Type 409(P7 to P7) with New GTAW Filler Metal ER 409Nb. See Photos on Incorrect Filler Metal as Originally used.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Incorrect Filler Metal being used, if Not Corrected/Repaired in timely manner at Vendor Shop.

© 2019 Fraza Inspection Company - All Rights Reserved