Project Detail

Project: North Forest Plant Boiler Y9ST-003.

Equipment: Boiler Burner & Fuel Gas Assembly

Date: January 2016 - April 2016

Vendor Location: Fabricator of Boiler Burner & Fuel Gas Assemblies in Queretaro, Mexico.

Review of WPSs and PQRs per ITP-35795-1045 Rev 1 Activity Number A5.

Item Inspected: Burner-Windbox Weldment.

Findings: Aspects Reviewed: Due to no effective communication at Vendor Facilities all welds Stainless Steel to Stainless Steel of Windbox Assy have been welded following a Welding Procedure identified as WPS-150.2 with GMAW process, which is not approved by Customer instead of the approved WPS-135A with GTAW process.

Re-Inspection: Vendor has generated a NCR for this non-conformance and per Customer Disposition, has cutted apart all SS Joints of Windbox removing the Weld material applied per the wrong WPS-150.2 by GMAW process and welded again in accordance with approved WPS-135A by GTAW process. See photos on described issue as originally found.

Final Check List on Burner Assy per ITP-35795-1045 Rev 1, Activity Number 4.0 and General Assembly Drawing NF-PB-1045 Rev 3.

Item Inspected: Burner Assembly.

Findings: Items 8(Ignition Enclosure), 23(Scanner Enclosure) and Hex Head Plug item 19, observed not yet installed in the Burner Assembly, since Vendor had considered such items as no included within their scope of supply.

Re-Inspection: Fraza Team has requested to Vendor Representative to review thoroughly about it per Project Requirements and finally the referenced items have been confirmed as within the scope of supply from Vendor and accordingly they have been assembled in the Burner Assy in accordance with referenced GA Drawing. See Photos on Described Issues after Corrections.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Not Approved Welding Procedures and Missing Items, if Not Corrected/Repaired in timely manner at Vendor Shop.

Project Detail

Project: South Forest Plant

Equipments: Variflame Burner Assembly

Date: August 2014

Vendor Location: Vendor Location: Fabricator of Burner Assemblies in Estado de Mexico, Mexico.

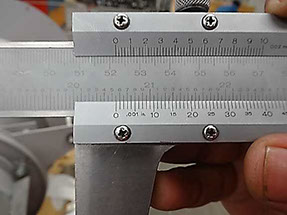

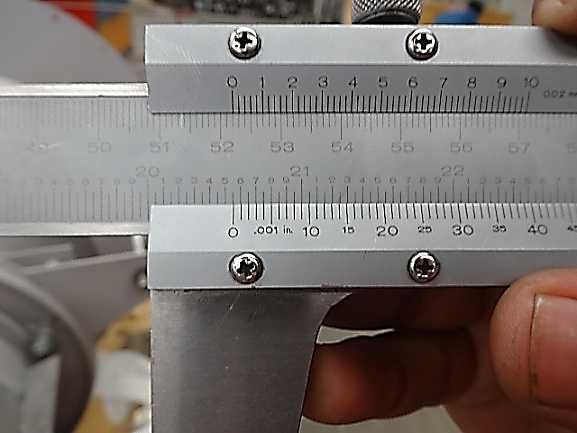

Dimensional Inspection on Circularity of Air Cone per ITP 5416419 Rev 0, Items 13 and 15 and Drawing 5416419-SF-01 Rev 1.

Item Inspected: Air Cone of Burner Assembly.

Findings: Overall outside diameter of Register Gussets, Specified Dimension, 20.590” plus 0.00/minus 0.06”, Actual Dimensions as Measured, Equipment Nr 1-20.650” to 20.665”, Equipment Nr 2-20.635” and Equpment Nr 3-20.625”, All of them Out of Tolerance per Referenced Drawing.

Re-Inspection: after Corrections: Equipment Nr 1-20.530” to 20.555”, Equipment Nr 2-20.550” to 20.569” and Equpment Nr 3-20.540” to 20.575”, All acceptable per Referenced Drawing. See Photos as illustration on Described Issue.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Dimensions, if Not Corrected/Repaired in timely manner at Vendor Shop.

© 2019 Fraza Inspection Company - All Rights Reserved