Project Detail

Project: Eagle Mountain Refinery

Equipments: 750BBL API 12F Water Tanks, Oil Inlet Tank and Oil Storage Tank

Date: January 2019

Vendor Location: Fabricator of Production API Tanks in Texas USA.

DFT and Visual Inspection on Painting per ITP-EMR-TK-Y75-01 Rev 1 Item 13.0 and Customer Data Sheet EMR-TK-DTS-Y7502 Rev 02.

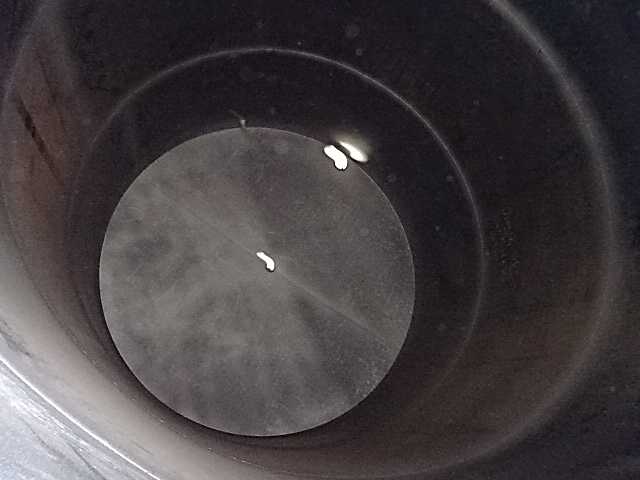

Inspected Item: 750BBL-API Oil Storage Tank Tag-R1916, Serial Number 195938(No Internal Pipe).

Findings: This Tank was delivered for Final Inspection by Fraza Team, however it was found not painted on underside of Roof, Not Acceptable to Customer Data Sheet EMR-TK-DTS-Y7502 Rev 02.

Re-inspection: Vendor has blasted and painted on underside of Roof in accordance with Paint System as specified per referenced Customer Data Sheet. See Photo on Issue as originally found.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Painting if Not Corrected/Repaired in timely manner at Vendor Shop.

Project Detail

Project: Eagle Pass Refinery

Equipments: 750BBL API 12F Produced Water Tanks, Oil Inlet Tank and Oil Storage Tank

Date: March 2019

Vendor Location: Fabricator of Production Water Tanks in Texas USA.

Visual and Dimensional Inspection per ITP-EPR-TK-T75-01 Rev 2 Item 08, Drawing 3413 Rev 2 and Customer Data Sheet EPR-TK-DTS-Y7501 Rev 02.

Items Inspected: 750BBL-API Oil Storage Tank Tag-R1918 and R1920 Serial Numbers 195958 and 195960.

Findings: Per Fabrication Drawing 3413 Rev 2, Page 3/14 Detail 16, Four Additional Walkway Brackets are specified to be installed for Tank R1918 at 90 Deg and R1920 at 270 Deg, which were not installed originally.

Re-Inspection: Installation of Referenced Additional Walkway Brackets by Vendor, completed on March 02, 2019. See Photos as illustration on Additional Walkway Brackets as Finally Installed.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on missing Walkway Brackets, if Not Corrected/Repaired in timely manner at Vendor Shop.

Project Detail

Project: North Valley Refinery

Equipments: API 650 Tanks

Date: December 2012 to July 2013

Vendor Location: Fabricator of API Tanks and Pressure vessels in Nuevo Leon, Mexico.

Dimensional Inspection per ITP-RYU-UL-W76-02 Rev 2 SEC Nr 6.1.16, Customer Specification GH8U-W76-01 Rev 1 and Drawing 0542-09-05 Rev C.

Items Inspected: Fabricated API Tanks.

Findings: Deviations of radial contour of vessel checked with a Radial Template measured at locations of all four vertical weld joints of Bottom Course: 13mm-Not Acceptable to Customer Specification GH8U-W76-01 Rev 1, Section 5.2.1.

Re-inspection: Corrections completed by Vendor to bring referenced Radial Contour Deviations to within Tolerances per Customer Specifications. See photos as illustration on referenced Issue.

Dimensional Inspection per ITP-RYU-UL-W76-02 Rev 2 SEC Nr 6.1.16, Customer Specification GH8U-W76-01 Rev 1 and Drawing 0542-09-05 Rev C.

Item Inspected: Fabricated API Tanks.

Findings: Deviations of axial contour of vessel checked with a Straightedge measured at several locations through the horizontal welded joints: At 270 Deg location: 8mm-Not Acceptable to Customer Specification GH8U Rev 1 Section 5.2.2.

Re-Inspection: Corrections completed by Vendor to bring referenced Axial Contour Deviations to within Tolerances per Customer Specifications. See photos as illustration on referenced Issue.

Dimensional Inspection per ITP-RYU-UL-W76-02 Rev 2 SEC Nr 6.1.16 and Drawing 0542-09-05 Rev C.

Item Inspected: Fabricated API Tanks.

Findings: Bolt-holes Circle Base-Diameter on Top Flange-Specified Dimension, 7169mm; Actual as Measured at Direction 90-270 Deg: 7243 mm, at Direction 0-180°: 7157 mm, Not Acceptable to tolerances per API 650 Section 7.5.3.

Re-Inspection: Corrections completed by Vendor to bring Bolt-holes Circle Base-Diameter to within tolerances per Project Requirements referenced Above. See photos as illustration on referenced Issue.

Visual Inspection per ITP-RYU-UL-W76-02-ITP Rev 2 SEC Nr 6.1.14 and Drawing 0542-09-05 Rev C.

Item Inspected: Fabricated API Tanks.

Findings: Issues Observed, porosity in welds, overlaps, arc strikes, welds on external gussets no seal welded all around on edges as specified, unacceptable undercuts, spatter, specified preparation on internal edges of some nozzles to achieve a radius ¼” mínimum-not completed, undersized fillet welds on nozzles.

Re-Inspection: All needed Repairs Completed by Vendor in accordance with Project Requirements . See Photos on referenced Issues.

Witness on Surface Preparation per ITP-RYU-UL-W76-02 Rev 2 SEC Nr 7.1.18, Vendor Surface Prep & Coating Procedure JA-KR-TY-23 Rev 1 and Customer Paint Specification HW763N Rev 1.

Item Inspected: Blasted API Tanks.

Findings: Tank Item HK-Tank-09, External Side, Specified Surface Preparation-SSPC-SP6-Commercial Blast Cleaning. Actual Surface Preparation as achieved-Several Areas in Shell Not in compliance to specified SSPC-SP6.

Re-Inspection: After corrections by re-blasting-Finally Satisfactory to SSPC-SP6 and Project Documents referenced above. See photos as illustration on referenced Issue.

Witness on Paint DFT Measuring per ITP-RYU-UL-W76-02 Rev 2 SEC Nr 7.1, Vendor Surface Prep & Coating Procedure JA-KR-TY-23 Rev 1 and Customer Paint Specification HW763N Rev 1.

Item Inspected: Painted API Tanks.

Findings: Tank Tag HK-Tank-10, Specified Total DFT-12 to18 Mils per referenced Customer Specification, Actual measured DFT-Several Areas on Shell, edges and back faces of Nozzle Flanges and Reinforcement Plate of Manhole with Low DFT of 6 to 8 mils.

Re-Inspection: Referenced áreas re-painted by Vendor to bring DFT within Specified Total DFT. See photo as illustration on referenced Issue.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Reworks at field site per unacceptable issues on welding, dimensions, surface preparation and painting if Not Repaired in timely manner at Vendor Shop.

Project Detail

Project: North Pass Refinery

Equipments: 500BBL API 12F Production Tanks

Date: March 2018 to May 2018

Vendor Location: Fabricator of API Tanks in Texas USA.

Visual Inspection per Inspection and Test Plan ITP-NPR-TK-Y50-02 Rev 2 Item 3.0, Customer Data Sheet NPR-TK-DTS-Y5002 Rev 01 and Drawing 7483 Rev 1.

Items Inspected: 500BBL API Production Tanks.

Findings: All Tanks observed with several locations with Rusting.

Re-Inspection: Repairs completed by Vendor by Sanding and Re-Painting in accordance with Paint Manufacturer Data Sheet and Project Documents Referenced Above. See Photos on Issues as Originally found.

Visual Inspection on Painting per Inspection and Test Plan ITP-NPR-TK-Y50-02 Rev 2 Item 13.0 and Customer Data Sheet NPR-TK-DTS-Y5002 Rev 01.

Inspected Item: 500BBL API Production Tanks.

Findings: Observed locations on all Tanks with Paint defects such as Runs and Sags.

Re-Inspection: Repairs completed from Vendor by Sanding and Re-Painting found acceptable to Project Documents Referenced Above. See Photo on described Issue.

Visual Inspection on Painting per Inspection and Test Plan ITP-NPR-TK-Y50-02 Rev 2 Item 13.0 and Customer Data Sheet NPR-TK-DTS-Y5002 Rev 01.

Inspected Item: 500BBL API Production Tanks.

Findings: All Tanks showing spots with No Full Paint Coverage.

Re-Inspection: Repairs completed from Vendor by Sanding and Re-Painting in accordance with Paint Manufacturer Data Sheet and Referenced Project Documents. See Photos on detected Issues as Illustration.

Visual Inspection on Painting per Inspection and Test Plan ITP-NPR-TK-Y50-02 Rev 2 Item 13.0 and Customer Data Sheet NPR-TK-DTS-Y5002 Rev 01.

Inspected Item: 500BBL API Production Tanks.

Findings: Areas on Bolts installed on Manway Cover producing Rusting.

Re-Inspection: Vendor has removed all defective bolts, nuts and washers producing rusting and new ones acceptable to Project Requirements have been installed. See Photos on described Issue.

Review of Documents per Inspection and Test Plan ITP-NPR-TK-Y50-02 Rev 2 Item 15.0 and Documents as referenced.

Items Inspected: Blasting/Painting Reports.

Findings/Conclusions: All Documents Acceptable to Project Requirements, Except Surface Preparation Reports which reflect on Specified Range for Anchorage Profile, 2.0 to 3.0 Mils per Customer Data Sheet NPR-TK-DTS-Y5002 Rev 01, Actual Profile Readings per Reports, 2.4 to 4.8 Mils, several of them higher than the maximum specified of 3.0 Mils, however, considered as no issue since the lowest Painting DFT applied is above 5.0 Mils, therefore all peaks per exceeded anchorage profile are fully paint covered.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Painting if Not Corrected/Repaired in timely manner at Vendor Shop.

Project Detail

Project: White River Canyon Refinery

Equipments: 750BBL API 12F Produced Water Tanks, Oil Inlet Tank and Oil Storage Tank

Date: May 2019

Vendor Location: Fabricator of Production Water Tanks in Texas USA.

Visual and Dimensional Inspection per Inspection and Test Plan ITP-WRC-TK-T75-04 Rev 2 Item 08, Drawing 3414 Rev 1 and Customer Data Sheet WRC-TK-DTS-S04 Rev 01.

Inspected Item: 750BBL-API Oil Storage Tank Tag-R1922 Serial Number 196019.

Findings: Tank found with wrong location of Coupling Number N6, specified location per referenced Drawing, 282" from Bottom, Actual location as Measured, 258"(Minus 24"). Not Acceptable to Project Tolerances.

Re-inspection: Vendor has completed on Correction to re-locate Coupling N6 at 282” as measured from Bottom in accordance with Drawing Requirements. See Photo as Illustration on referenced issue as originally detected.

Benefits to Our Customer: By using Fraza Inspection Team, Customer saved a lot of of time and money preventing excessive expenses per back charges for Re-works at field site per unacceptable issues on Dimensions, if Not Corrected/Repaired in timely manner at Vendor Shop.

© 2019 Fraza Inspection Company - All Rights Reserved