"Unwavering Passion and Enthusiasm for the Service since 1987"

Fraza Inspection Company is a Global Company providing support services of Inspection and Expediting in the Quality Field, targeted to the Power Generation, Oil & Gas, Renewables, Construction, Mining and Petrochemical Sectors.

With a clear focus of our efforts towards the Sectors referenced above, seeking full satisfaction to the requirements of our clients, we work closely with them, keeping our communication channels always open and attentive to any comments or feedback which are very valuable quality information that allows us to continue advancing in our process of continuous improvement.

Since its foundation in 2019, at Fraza Inspection Company we strive through our daily performance to consistently improve our global capabilities and achieve every day the highest level of participation and responsiveness to our customers, as required by the business requirements of a increasingly globalized market.

Having as our fundamental objective a consistent satisfaction of our Clients, our services are strategically structured and focused to improve the Business Performance of our Clients, based on improving the expectation of performance and durability of the inspected goods as well as the corresponding reduction of risks.

Our main strategy is to work closely with our clients, analyzing and understanding in depth their requirements, consistently taking into account factors such as project financing, costs, geographic location of suppliers, which affect the making of their business decisions, accordingly, adapting our technical and commercial capabilities to their specific needs, in other words we make a suit tailored to each of our clients.

With a clear focus on a careful attention to Global Projects, Fraza Inspection Company has staff members fluently speaking English and Spanish.

c

f

i

Contributions to Our Customers

Strainers

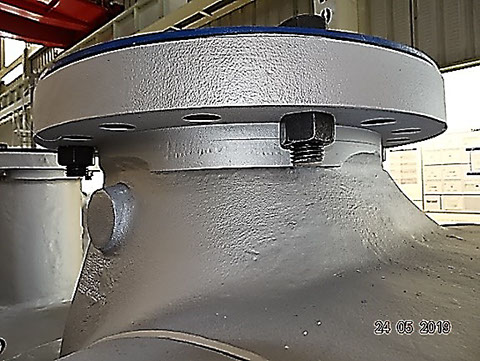

Project: Western Union Unit 02

Equipments: Strainers

Date: May 2014 to September 2014

Vendor Location: Fabricator of Pressure Vessels in Tamaulipas, Mexico.

Contribution to our Customer:

Witness on Hydrostatic Test per ITP-WU-194-QS-01-Item 06 and Hydrostatic Test Procedure QWU-193.8 Rev B.

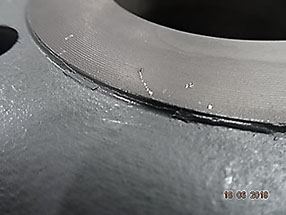

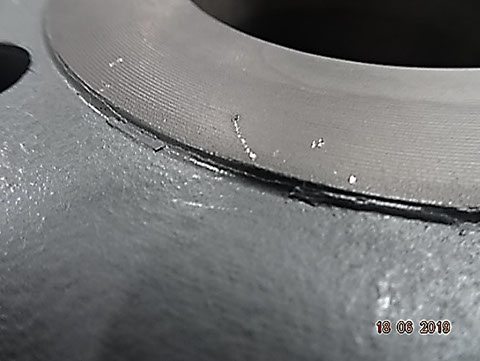

Item Inspected: Strainer Tag-195-WU-01, Serial Number T44098.

Findings: Pressure Drop/Leaks detected on Weld of Outlet Nozzle to Pipe Body. Steps conducted by Vendor and Witnessed by Fraza Team to get properly Repaired the Weld Defects Producing Leaks: Grinding to Remove completely the lack of fusion. PT Exam on Explored Weld to confirm on sound metal. GTAW Welding on Explored Weld from Inside and Outside. PT Exam on Completed Weld Repair. A hydrotest conducted again per Project Documents, With No leaks and No Pressure Drops detected. See Photos on Leaks as originally Detected.

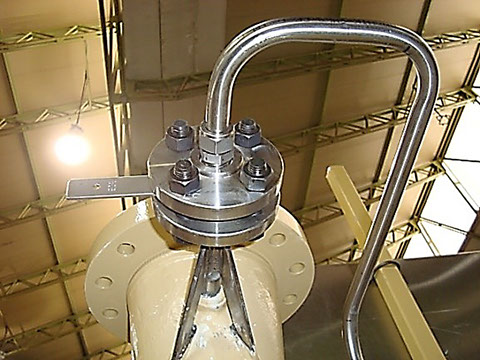

Project: Western Union Unit 02

Equipments: Strainers

Date: May 2014 to September 2014

Vendor Location: Fabricator of Pressure Vessels in Tamaulipas, Mexico.

Contribution to our Customer:

Witness on Hydrostatic Test per ITP-WU-195-QS-01-Item 06 and Hydrostatic Test Procedure QWU-193.8 Rev B.

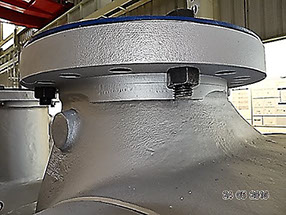

Item Inspected: Strainer Tag-195-WU-01, Serial Number T44099.

Findings: Four Focused Locations with Leaks detected on Base Metal of Casting Lower Manifold. Vendor QC Team has issued an NCR, and per Customer Disposition the Lower Manifold Casting and all components welded to it have been replaced by Vendor. After Replacing of referenced ítems, Hydrotest has been conducted again per Project Documents, with No leaks and No Pressure Drops Detected. See Photos on Leaks as originally Detected.

Air Inlet Filter Equipments

Project: North Mountain Energy Project

Equipments: Air Inlet Filter Equipments

Date: May 2012 to to April 2013

Vendor Location: Fabricator of Air Inlet Filter Equipments in Cohahuila, Mexico.

Contribution to Our Customer:

Final Visual Inspection per ITP-104043-01 Rev 1 Item 19.

Item Inspected: MTT Filter Modules MTT-128-6, MTT-128-9 and End Filter Modules.

Findings: Loose Hardware left within Clean Air Chamber of MTT-128-9 Filter Module as well a Nut Not Properly Captivated by the tack weld applied at the screw end on Clean Air Chamber of Middle Filter Module. Fraza Team has requested to Vendor to be extremely careful to ensure no loose hardware are left within the Clean Air Chamber of Air Inlet Filter Equipments after closure. This is to prevent loose items migrate toward the turbine and cause irreparable damage on it. See Photos on Referenced Issue.

Project: High Valley Energy Unit 03

Equipments: Air Inlet Filter Equipments

Date: Januray 2018 to June 2018

Vendor Location: Fabricator of Air Inlet Filter Equipments in Coahuila, Mexico.

Contribution to our Customer:

Visual Inspection on Trial Assembly per Vendor ITP-HV-78506 Rev 1, Item 9 and Drawing HVE-452T05-01 Rev 3.

Items Inspected: Trial Fitted Inlet Transition.

Findings: Both interface points where converge the three transition panels R/HV05-16, R/HV05-18 and R/HV05-22 show Openings of 1” x 2” approximately. These Openings are a serious risk to get contamination with dirty air from exterior toward Air Clean Chamber in Transition. Repairs completed properly by Vendor to prevent this risk of contamination with dirty air. See Photos as Illustration of Referenced Issue as originally found.

Project: Lowland F80 Unit 02

Equipments: Air Inlet Filter Equipments

Date: January 2019 to March 2019

Vendor Location: Fabricator of Air Inlet Filter Equipments in Nuevo Leon, Mexico.

Contribution to our Customer:

Witness on Pneumatic Test on Air Manifold Assy per Vendor Quality Plan QCIP 162234 Rev 0 Item 10.4 and Documents referenced below.

Item Inspected: Air Manifold Assy of Filter Module.

Findings: A Not Acceptable loss of pressure per leak located on the weld of square tube to end cover plate. The pressure was lowered to zero, the area with leak repaired by welding and the Pneumatic Test conducted again, with No Leaks/Pressure Drops Detected. Repaired Area on Manifold has been Re-Coated by Spray Cold Galvanizing per Project Requirements. Test Pressure, 100 Psi, Holding time of 15 Minutes, per Vendor Standard 3LL-AT-6.7 Rev 2, section 6.2. See Photo of Leak originally detected.

Turbine Flow Meters

Project: Blue Beauty Beach Unit 02

Equipments: Turbine Flow Metters

Date: March 2019 to June 2019

Vendor Location: Fabricator of Turbine Flow Metters in Chihuahua, Mexico.

Contribution to our Customer:

Final Inspection per ITP-386590 Rev C Item IX and Drawing TFM-B55112-01 Rev C.

Items Inspected: Turbine Flow Metter Serial Number N15-TFM-3276.

Findings: Imperfections observed on Flange Facing Finish of 0.180” long exceeding the Maximum allowable dimension of radial projection of 0.059” for imperfections per section 6.4.6/Table 3 from ASME B16.5 Standard for Flanges 3”-150#. Vendor Team has decided to Rework the affected Flange Facing Finish by Machining. After Rework, Flange Facing Finish measured and found with Average Roughness of 234 Micro Inches and Height of Raised Face of 0.049”, both Dimensions OK to ASME B16.5 Std. Also, a Hydrotest conducted again per Project Requirements with acceptable results. See Photos as Illustration on Described issue as originally found.

Exhaust Systems

Project: High Land Unit 02

Equipments: Exhaust System Equipments

Date: October 2017 to November 2017

Vendor Location: Fabricator of Exhaust System Equipments in San Luis Potosi, Mexico.

Contribution to our Customer:

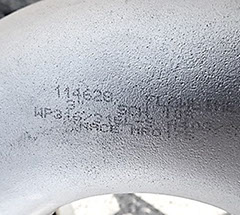

Verification on Sizing/Rating, Material Traceability markings on Connection Nozzles per Vendor ITP-HL-35J612 Rev E, Item 05 and Drawing HL-3545-02 Rev 1.

Items Inspected: Ducts with Ports Item 7455401 and 7455402.

Findings: Blind Flanges 6” 150#, Heat Number 6201 in Wrong Carbon Steel Material ASTM A-105 were originally installed on Port Nozzles. Re-Inspection: Wrong Blind Flanges in CS Material A-105 have been removed and Right Flanges 6” 150#, in right Low Alloy Material ASTM A-182 Grade F22 have been Installed per Vendor BOM and Drawing HL-3545-02 Rev 1. See Photos as Illustration on described Issue.

Project: North Pass Energy Unit 02

Equipment: Exhaust System Equipments

Date: May 2012 to September 2012

Vendor Location: Fabricator of Exhaust System Equipments in Nuevo Leon, Mexico.

Contribution to our Customer:

Trial Fit Inspection per ITP-5092-01 Rev 2 Item 8 and GA Drawing GA-UK-9705 Rev 3.

Items Inspected: Exhaust Transition Item 42-Elbow Duct Item 52-Exhaust Elbow Transition Item 62 Trial Assembled/Bolted together.

Findings: An evident mismatch between Mating Flanges of Transition Item 42 to Elbow Item 52. Per Fraza Team request, Vendor has installed 100% of the bolts/nuts on all boltholes of all interfaces flanges, detecting an important deviation existing between the lines of boltholes of both Equipments trial assembled together. To fix the Existing Deviation, the location of 16 bolt holes has been corrected on outlet flange of Transition Item 42. After corrections, all Three Equipments have been placed/bolted together again to complete on acceptable Trial Fit Inspection. See Photo as Illustration of Referenced Issue.

Heat Exchangers

Project: White Horse Mountain Unit 03

Equipments: Oil Cooler, Economizer, Accumulator

Date: October 2014 to November 2014

Vendor Location: Fabricator of Heat Exchangers in Durango, Mexico.

Contribution to our Customer:

Witness on Pneumatic Test per ITP WHM-1176-593-006 Rev 2, Activity Number 8.13 and GA Drawing 748W0342 Rev D.

Item Inspected: Oil Cooler Tag Nr WHM-2177, Pneumatically Tested on Tubes Side.

Findings: Test pressure taken to MAWP of 229 psi, detected a leak at a pipe nozzle of shell side. Leak produced by failures on expanded joints of Tubes to Tubesheet, transmitting pressure from tubes side to shell side. Vendor has corrected the failures found on joints of Tubes to Tubesheet and Pneumatic Test conducted again per Project Requirements with Acceptable Results. See Photo as illustration of Leak as originally found.

Painting

Project: Beauty High Mountain Unit 03

Equipments: Pumps

Date: September 2018 to May 2019

Vendor Location: Fabricator of Pumps in Estado de Mexico, Mexico.

Contribution to our Customer:

Review on Paint Systems per Vendor ITP 790033-010 Rev 2, Item 2.1 and Approved Painting Procedure BHM-040-R-050A Rev C.

Item Inspected: Pump Tag BHM-60-T-0310-A/B/C.

Findings: Specified Paint Systems per Approved Paint Procedure BHM-040-R-050A Rev C are: Case and Cover, Paint System BHCS-22C- Surface Prep: Clean to SSPC-SP1-Primer: International Intertherm 751 CSA. Bearing Housing, Paint System BHCS-4A, Surface Prep to Sa3, Primer, Hempel Hempadur 85671. Due to a lack of communication between Main Vendor and Manufacturer in Mexico, Wrongly, a Paint System per Paint Spec BQS-76-03-010 Rev 0 with Primer, International Interzinc 22 has been applied by Mexican Manufacturer on Casing, Cover and Bearing Housing. Per Customer Disposition, Referenced Items have been Re-Blasted and Re-Painted per Paint Systems of Referenced Approved Painting Procedure BHM-040-R-050A Rev C. See Photos Before and After Re-Work on Paint.

Project: Deep River Unit 03

Equipments: Pumps

Date: June 2018 to May 2019

Vendor Location: Fabricator of Pumps in Nuevo Leon, Mexico.

Contribution to our Customer:

Final Visual Inspection per Inspection Plan ITP 216-RU-1023A/B Rev 2.

Items Inspected: Pump Tag DR-1023-A/B, Serial Number 452612-1/2, Nozzle Header.

Findings: Suction/Vent Nozzles-Flanges, Observed with Flange Facing Finish seriously damaged, apparently the gasket seats finish was exposed to the action of Blasting during Surface Preparation. Per Customer Disposition on issued NCR-1023-01, the Flanges damaged have been cutted off and new flanges have been installed/welded. As well a new Hydrotest has been conducted for the Reworked Nozzle Header. See Photos on Referenced Issue as originally found.

Pressure Vessels

Project: South High Mountain Energy Project

Equipments: Steam Drum, Heat Exchanger, Lower Drum, Pre-Heater and Steam Super Heater.

Date: April 2016 to October 2016

Vendor Location: Fabricator of Heat Exchangers and Pressure Vessels in Nuevo Leon, Mexico.

Contribution to our Customer:

Dimensional Inspection per ITP-1473 Rev 1 Sec Nr 4.0, Drawing 1472 Rev G and Spec 19502-HE-03 Rev 2.

Item Inspected: Steam Drum Tag S-8804.

Findings: Nozzle N19, Dimensions of Flange Item 23 such as Diameter of Boltholes Circle and Outside Diameter do not match with dimensions of connecting flange ítem 9 installed in piping continuous blowdown per drawing 1472 Rev G. This is a mistake in drawing since the dimensions of referenced flange item 23 correspond to a size NPS 2” 150# and the connecting flange item 9 corresponds to a size NPS 1 1/2” 150#. Per Vendor Engineering a new flange item 9 with similar dimensions as connecting flange item 23 will be fabricated and this change will be reflected on revised drawings. See Photos on Referenced Issue.

Pumps

Project: Bankok West Project Unit 03

Equipment: Reflux Pumps

Date: July 2009 to March 2010

Vendor Location: Pumps Fabricator in Estado de Mexico, Mexico.

Contribution to Our Customer:

Review on RT Examination per ITP-1852-01 Rev 5, Item 6.2, GA Drawings GA-852010-01 Rev B and Customer Specification NT-20-05-03 Table 3.

Item Inspected: Pumps Tag NTP 59A/B, Casings-31898-1/2:

Findings: RT Examination Reports does not reflect on RT Exposures for Critical Areas Number 3, 4 and 5 required to be RT Examined per Vendor ITP 1852-01 Rev 5 Item 6.2 and Customer Spec NT-20-05-03 Table 3. Vendor has confirmed unfortunately for some reason RT Examination on referenced Critical Areas has been omitted. Per Customer Disposition on Issued NCR, the referenced pumps have been disassembled in order to complete the RT Exposures on referenced Critical Areas. RT done with aceptable results. See Photo on RT Examination as Completed per Fraza Team Observation.

Project: Bankok West Project Unit 02

Equipment: Reflux Pumps

Date: July 2009 to March 2010

Vendor Location: Pumps Fabricator in Estado de Mexico, Mexico.

Contribution to our Customer:

Visual Inspection per ITP-11623-0030 Rev 2, Item 2.2, GA Drawings GA-630-01 Rev B and Vendor Paint Specification QPS-1623-0030 Rev 1.

Item Inspected: Pump Tag GHP 47B

Findings: ¾¨ Nozzle-Connection on Plans found gusseted only in one location Not in accordance with Drawing GA-630-01 Rev B which specifies for gusseting in two locations. Vendor has repaired on Pump GHP-47B to place/weld a 2nd gusseting on referenced Nozzle. Per Fraza Team Observation and Customer Disposition, Vendor has conducted a Re-Hydrotest per API-610 Standard Section 5.4.3, per welding done after original Hydrotest. See photos below as illustration on referenced issue before/after Re-work.

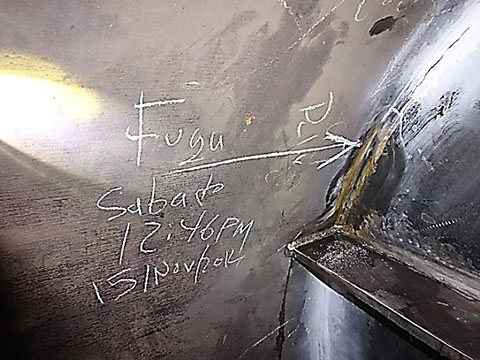

Stacks

Project: Beauty High Lake Unit 01

Equipments: Sub Stack and 16” Gas Riser Assembly

Date: August 2016 to October 2016

Vendor Location: Fabricator of Stacks and Piping Items in Coahuila, Mexico.

Contribution to our Customer:

Visual Inspection per ITP 841716 Rev 1 Item 012 and Drawing 841716-BHL-1-716-0001 Rev 0.

Item Inspected-Stack Section Number 2.

Findings: Toe of Fillet Weld of Field Connection Flanges to Shell plates observed just at ends of Flange Boltholes; This condition will produce an interference with the Bolts Head or Nuts to be installed to fasten together both Stack Sections. After detection by Fraza Team of this Engineering Issue, per Customer Direction, preventing the interference issue during the Field Erection, Vendor has fabricated a set of Spacer Flange Sections and assembled/bolted them together with the existing flanges on Connection Interface of Stack Section Number 1 to Section Number 2. See Photos below as illustration.

Project: Beauty High Lake Unit 01

Equipments: Sub Stack and 16” Gas Riser Assembly

Date: August 2016 to October 2016

Vendor Location: Fabricator of Stacks and Piping Items in Coahuila, Mexico.

Contribution to our Customer:

Visual and Dimensional Inspection per ITP 841716 Rev 1 item 19 and Drawing 8416-BHL-01 Rev 0.

Item Inspected: Stack Section Number 2.

Findings: On Trunnion Item number 9 was used a Pipe 14" Sch XS(0.500") instead of Specified Sch 80(0.75"); As per Explain from Vendor QC Team this Pipe Material 14" with a Wall Thickness thinner than the specified one, Wrongly was taken from existing stock with No Previous Inspection by Vendor QC Team. Per Customer Disposition on Issued NCR, the referenced Pipes 14" Sch XS (0.500") have been removed from trunnions and New Pipes 14" Sch 80(0.75") as specified have been installed/welded per Drawing 8416-BHL-01 Rev 0. See Photos as Illustration on Described Issue.

Project: Beauty High Lake Unit 03

Equipments: Back and Front End Flare Stacks, Derrick Structure and Ladder & Platforms

Date: July 2014 to January 2015

Vendor Location: Fabricator of Stacks and Structure in Nuevo Leon, Mexico.

Contribution to our Customer:

Witness on Hydrostatic Test per ITP-5394416 Rev 1, Item 15 and Customer Inspection Procedure BHL-FS-04416 Rev 0.

Item Inspected: Front End Flare Stack Assembly-60”-OD-Section A.

Findings: Observed Leaks on two locations of Weld of Floor Plate to Stack Shell. Per suggest from Fraza Team, UT Examination on referenced Weld has been conducted to confirm on Specified Full Penetration. UT Examination results reflect on lack of penetration on several spots of referenced weld included both locations observed originally with Leaks. Vendor has done all needed Repairs, conducting a back gouging to sound metal and re-welding on all locations per Hydrotest and UT Examination findings. After Completion on Repairs, hydrotest conducted again with acceptable results. See Photos as Illustration on Areas Observed Originally with Leaks.

Project: Beauty High Lake Unit 02

Equipments: Quench Stack with Refractory, Stack 48” OD, SCR Duct and Platform & Ladders

Date: August 2016 to January 2017

Vendor Location: Fabricator of Stacks in Coahuila, Mexico.

Contribution to our Customer:

Dimensional Inspection per ITP 232619 Rev 0 Item 014 and Drawing 2319-01 Rev 0.

Item Inspected: Square Duct-Boltholes Pattern on Field Connection Flanges.

Findings: On Vertical flanges, 18 Boltholes evently spaced are specified per Drawing 2310-01 Rev 0, however, Wrongly 19 Boltholes were done on all Four Vertical Flanges. Not Acceptable to Drawing 2319-01 Rev 0. Per Customer Direction, Vendor has cutted off the existing Vertical Flanges and new Flanges with correct bolhtoles pattern per referenced drawing have been installed and welded. See Photo on described Issue.

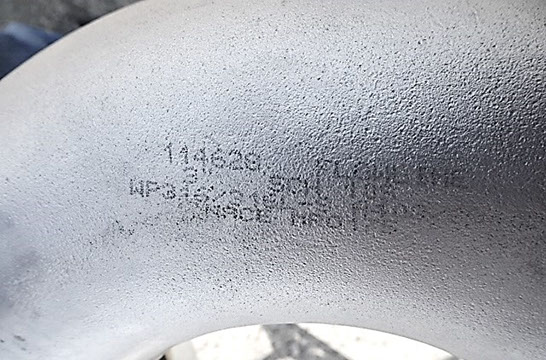

Project: Lake Charless Unit 01

Equipments: Stack/Blower Duct/Riser Piping

Date: February 2014 to May 2014

Vendor Location: Fabricator of Stack Equiments in Nuevo Leon, Mexico.

Contribution to our Customer:

Review on Project Requirements per Inspection Plan ITP-LC-8891-01 Rev 2, Item Number 1.1 and Drawing 8891-LC1-01 Rev 0 Air Gas Riser.

Item Inspected: Gas Riser Equipments-Purchasing Documents.

Findings: Per Drawing 8891-LC1-01 Rev 0, all Pipe/Fitting Items for Gas Riser are specified to be in Schedule 40 wall thickness, however per an incorrect interpretation of Project Requirements, Vendor had been purchasing all pipe/fitting ítems in schedule 10. Per Observation from Fraza Team, Vendor has corrected the Purchase Documents to reflect on Right Schedule for all Pipe Items in accordance with Project Documents. See Photos on Some Pipe/Fitting Items as Received at Vendor Facilities.

VIEW MORE

Through these 32 years of business trajectory...

We have achieved a Huge Expertise and Recognized Competences in Inspection and Expediting of a wide range of Equipments such as Christmas Trees, Stacks, API Tanks, Viscosity Analyzers, Exhaust & Inlet Systems, Pressure Vessels, Heat Exchangers, Expansion Joints, Burners, Coke Drums, Valves, Piping & Fittings, Rotating & Electrical Equipment, Structures as well as others. Additional information and details on our capabilities and experience can be found within our Links of Inspection Services and Inspection Gallery.

READ MORE

SERVICES

AUDITING

Fraza Inspection Company offers Auditing Services on Systems and Processes through periodic verifications to ensure that a Quality, Health, Safety and Environment Management System ...

READ MORE

EXPEDITING

Fraza Inspection Company offers Expediting Services at manufacturing facilities or on desk to ensure the requirements of delivery time from our Clients are fully met, which significantly increases ...

READ MORE

INSPECTION & SURVEILLANCE

Fraza Inspection Company offers Inspection Services at manufacturing facilities to ensure national and international standards as well client specific requirements are fully met, which exponentially improves ...

READ MORE

Certifications

Coating

NACE Level 1 & 2

READ MORE

Welding

CWI QC1. AWS

READ MORE

Nondestructive Testing

VT Level I & II. SNT-TC-1A

PT Level I & II. SNT-TC-1A

MT Level I & II. SNT-TC-1A

UT Level I & II. SNT-TC-1A

RT Level I & II. SNT-TC-1A

READ MORE

Welding

API 510

READ MORE

Aramco

QM03 Mechanical - General

QM06 Fabricated Piping (01)

QM15 Structural Steels (12)

QM26 Rotating Equip-Pumps (79)

QM30 Pressure Vessels (32)

QM31 Heat Exchangers (32)

QM34 Tanks

QM35 Skid Mounted Equipment – Mechanical

QM37 Relief Valve,Control Valve(34)

QM42 VID-Wellhead Equipment (45)

QM43 Quality System Assessor

READ MORE

Leave us your message or directly contact to our offices, we´ll be glad to assist you.

REQUEST A QUICK QUOTE

© 2019 Fraza Inspection Company - All Rights Reserved